|

YX-Q Flat Knitting Machine Series

brief introduction:

- The YX-Q series equipment is a fully formed computerized flat knitting machine independently developed by YONTHIN Technology, which is highly efficient, stable, and easy to use. It is widely used for weaving integrated woolen sweaters, seamless hats, scarves, socks, gloves, and more.

- In "YX-Q", "YX" represents YONTHIN, and "Q" represents fully formed

- Remote Control

- Online Centralized Monitoring

- Pattern Design System

- Efficient production

- Cost saving

- Product diversity

- Stable quality

- Energy conservation and environmental protection

What can I do with YONTHIN knitting machine?

Imagination is infinite, as long as you can imagine, you can knit.

Yonthin is widely used in weaving integrated woolen sweaters, seamless hats, scarves, socks, gloves, etc.

Why is it good at knitting?

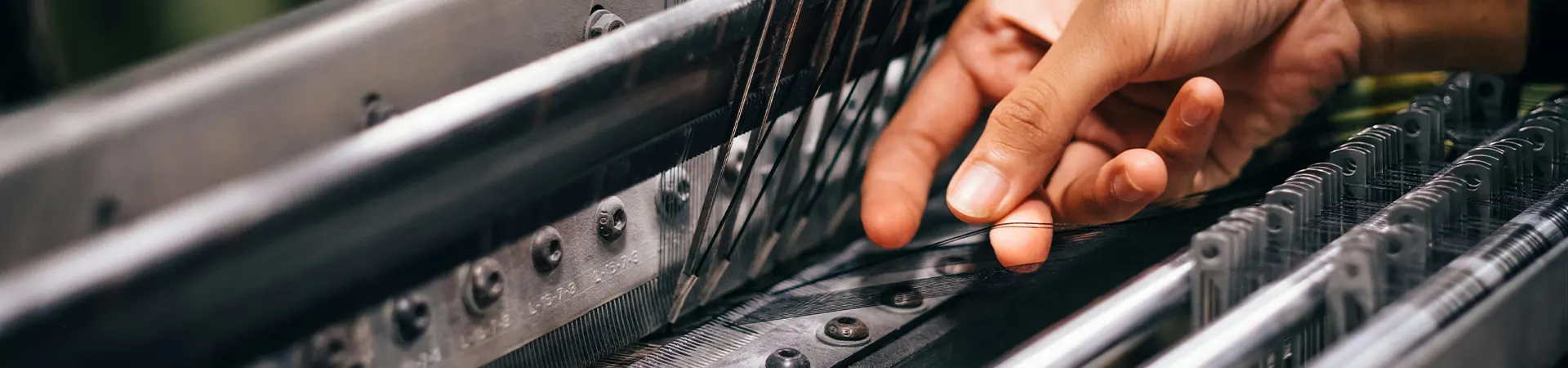

Every factor affecting knitting accuracy has been taken into consideration.

Control system, transmission system, motor, cam, etc,Where you cannot see are details.

|

|

|

|

|

Product advantages

|

|

|

|

|

|

|

Product Parameters

YX-Q Series | YX-Q G12 | YX-Q G14 | YX-Q G16 | YX-Q G18 |

Stitch length | 12G | 14G | 16G | 18G |

Number of stitches/ breadth | 12-needle/88-inch | 14-needle/88-inch | 16-needle/88-inch | 18-needle/88-inch |

Machine speed | Segmental adjustment, maximum speed: 1.6m/s, 255 segments of programmable speeds. | |||

Braiding system | Single-head and three--system, improve braiding efficiency of multi-color jacquard stitch greatly by implementing two-stitch braiding every one reverse stitch or one-stitch braiding every two reverse stitches. | |||

Shaking table | Motor driven, maximally 2 inches, rack up 1/2 and 1/4 needles at any positions. | |||

Sinker | The sinker system is controlled by the stepping motor, implement braiding of three systems in accordance with different fabrics, use different sinking pressures when transferring the stitch. | |||

Selector | 8-segment electronic selector. | |||

Tensioning device | segmental adjustment, High-position roller, segmental adjustment, auxiliary roller. | |||

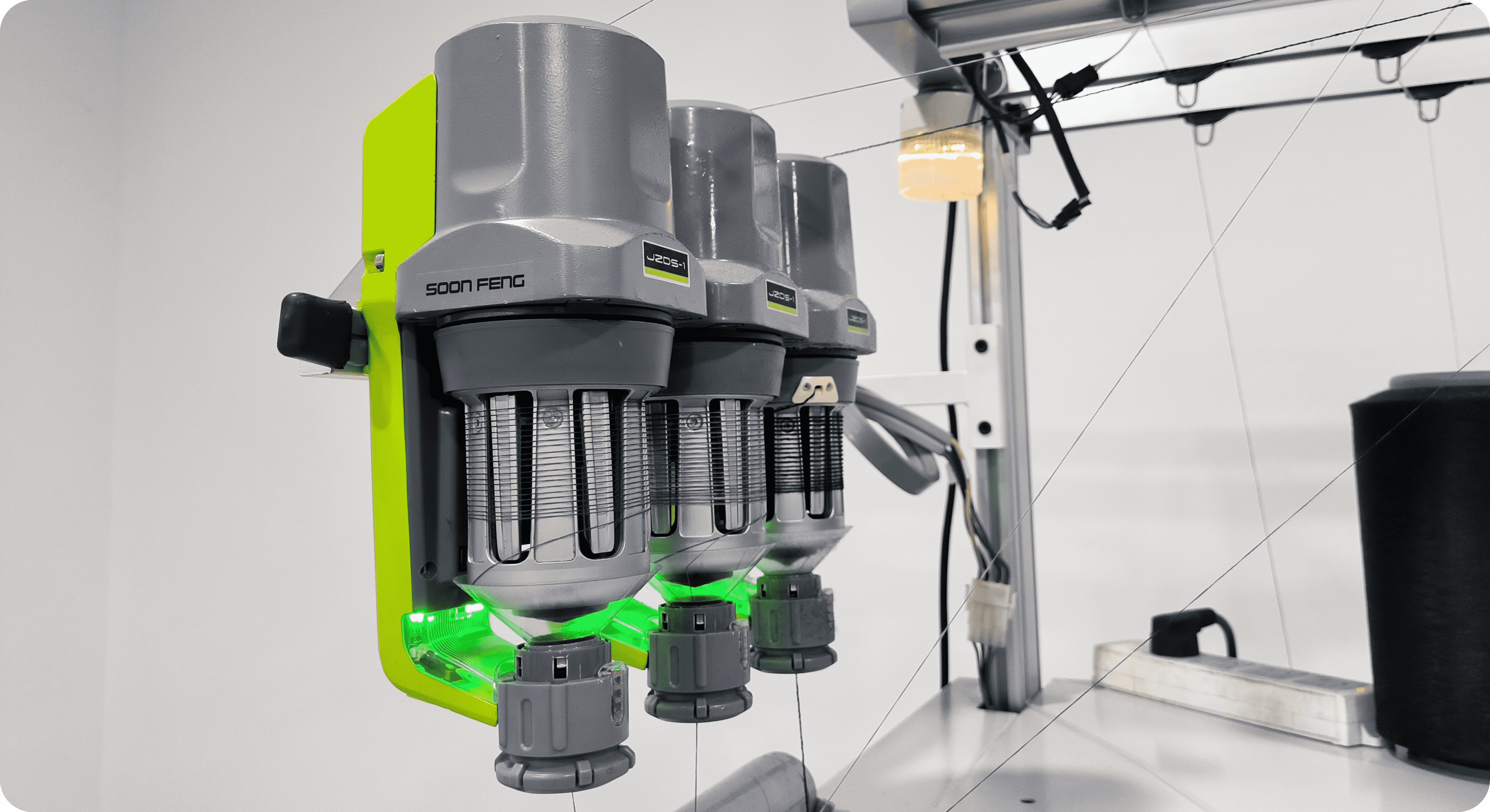

Yarn feeding device | The yarn storage device and the weft storage device (optional) contral the tensioning force of the yarn accurately to ensure consistency of quality of the whole fabric. | |||

Automatic stopping device | Automatic stop when meeting broken yarn, knot, batching, complefion, colision, overload, specifed traveling andstopping, program error, and other errors. | |||

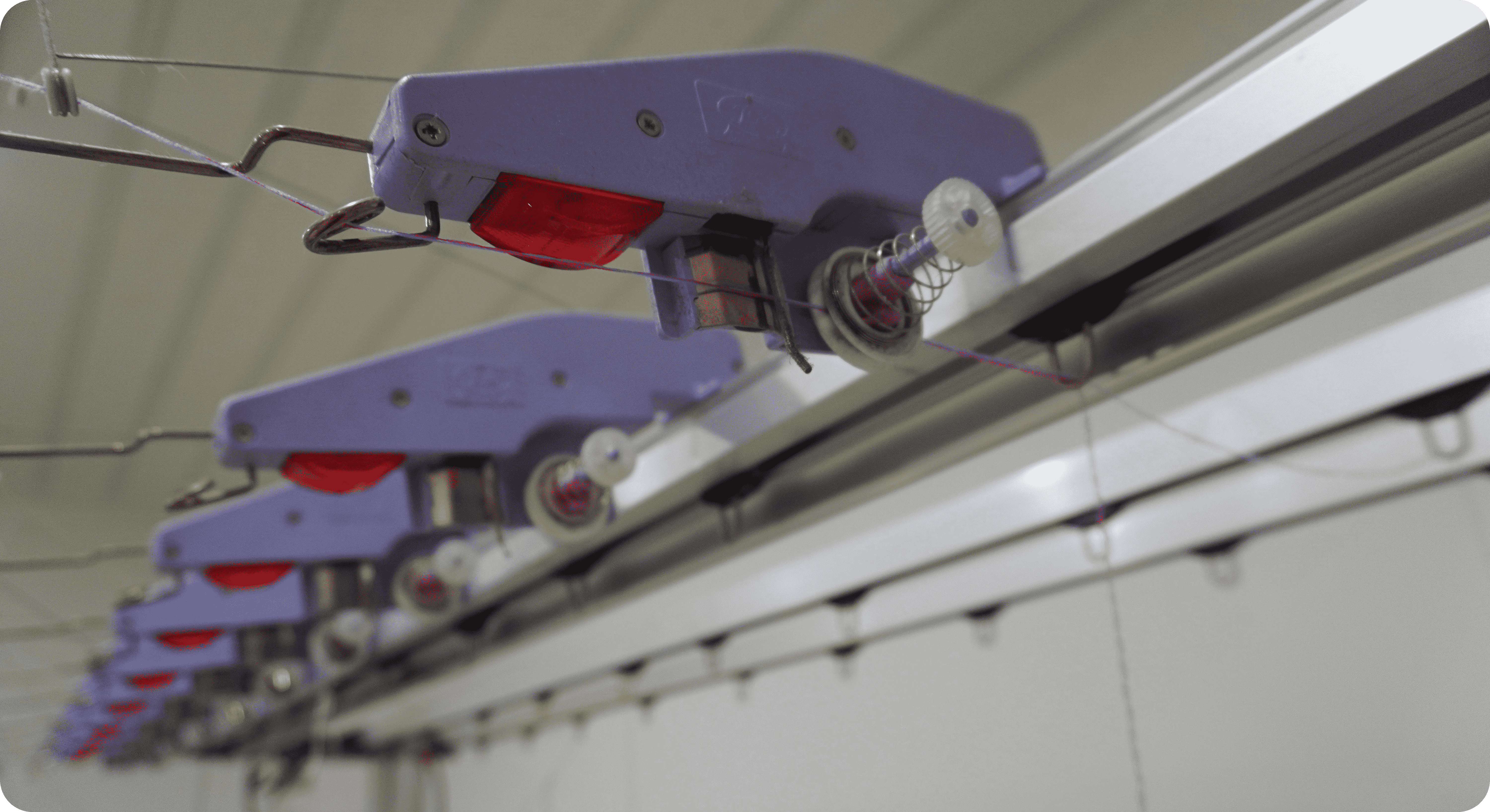

Yarn nozzle | The system can adiust the stopping position of the yarn nozzle during braiding on the machine. | |||

| Through this function, the yarn nozzle can follows up two sides of the fabric closely at any time, without making any complicated adjustment. | ||||

| On the basis of this characteristic, we can save a plenty of time on adjustment of design parameters of the machine, especially some complicated design. | ||||

| The system can complete braid multiple yarn nozzles in identical line and can braid the complicated design, such as appliqu é and knit & wear pattern easily, thereby improving the production efficiency greatly. | ||||

Transmission device | Transmission in presence of belt, control with AC servo motor. | |||

Safety device | The whole safety device is covered, thereby reducing noise and avoiding dust, the protective cover has the stopping sensor for stopping when meeting emergency, turning off the power supply device and indicator lamp. | |||

Data input | The computer accesses to the input data through the USB flash disk. | |||

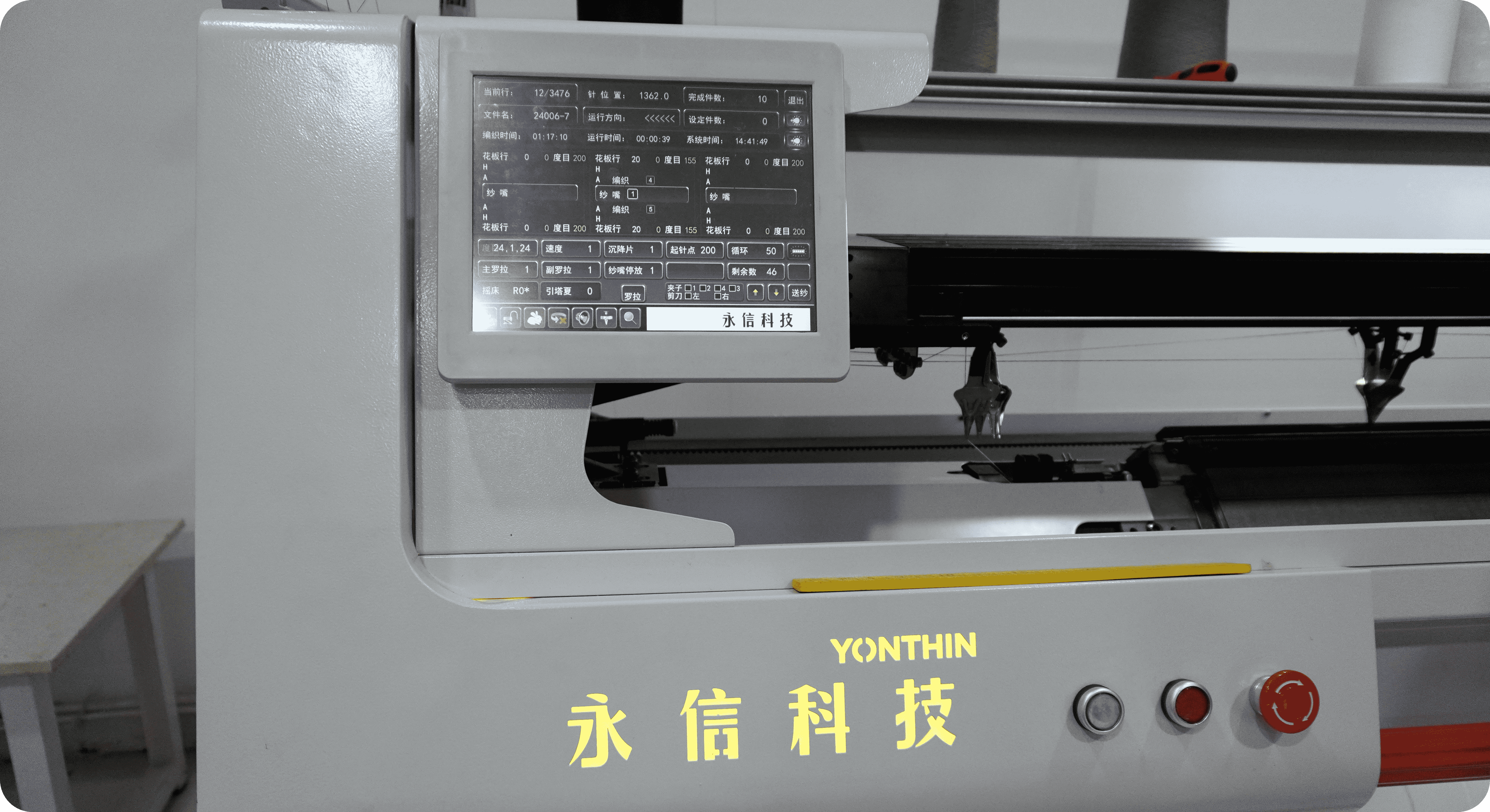

Control system | LCD industrial display is taken as the screen, the touch screen has the graphic interface, the USB flash disk or network is taken to transmit, the memory of the system is expanded to 2G, in order to store a plenty of design files and call out for use at any time in accordance with production need. | |||

| Monitoring of screen:various operating parameters and stitches under braiding can be displayed and adjusted at any time when the machine runs, thereby facilitating operation and saving time maximally. | ||||

| Multi-language operating version: the machine is compatible with versions in Chinese, English, ltalian, etc., and the version of needed language can be increased in accordance with the need of the customer. | ||||

Size and weight of the machine | width: 895mm, height: 1900mm, Volume: length: 2565mm, net weight: 1320kg | |||

Power supply device | frequency:50Hz/60Hz, Voltage:AC 220V, power:1.5KW | |||

Know us, Choose us, Be us

Sign up to receive the latest news, announcements, and promotions!