|

High Speed Open Width Knitting Machine

brief introduction:

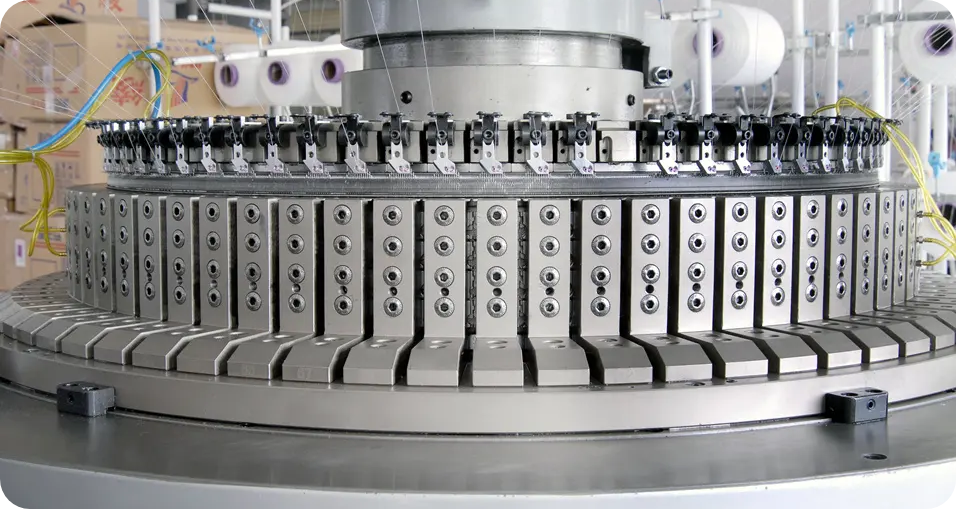

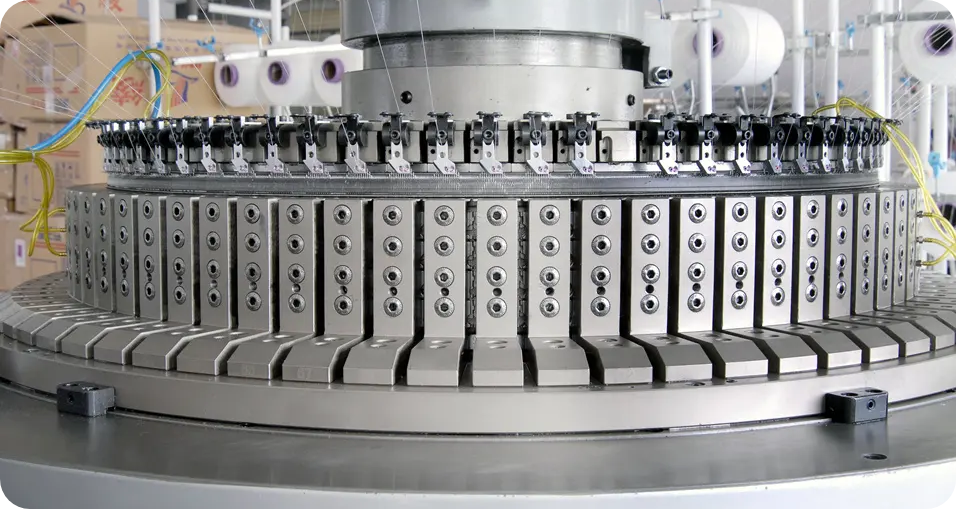

- Open width single jersey circular knitting machine with 3/3.2 feeders per diametrical inch

- Cam box design to receive up to 4 cam tracks on the cylinder

- The machine has all the characteristics of single jersey machine and crease-free for cloth of open width machine

- Advanced equipment support

- Advanced production technology

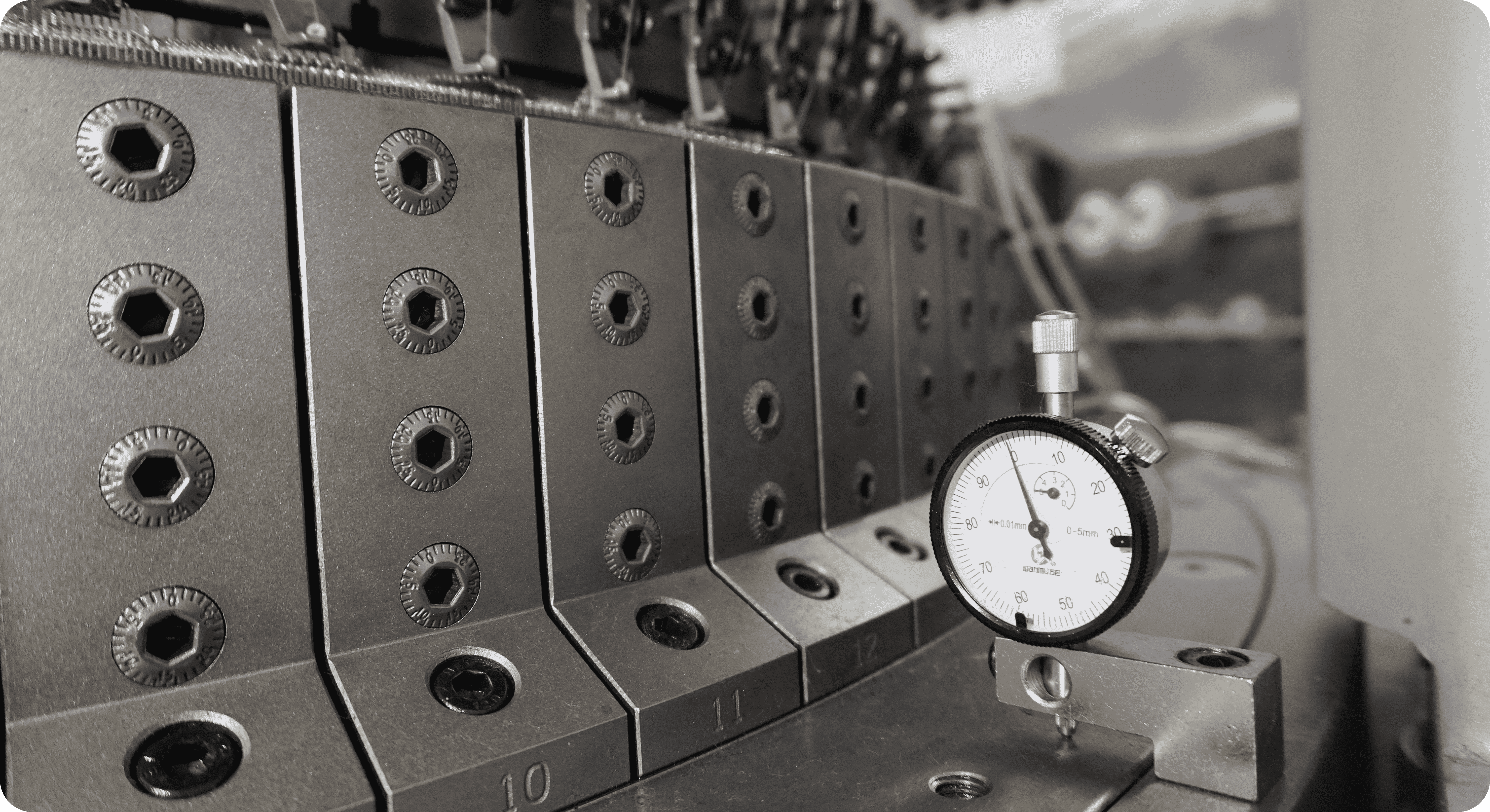

- High standard quality control and inspection

- Multiple optional devices

- High working speed

What can I do with YONTHIN circular knitting machine?

Imagination is infinite, as long as you can imagine, you can knit.

Produce various fabrics using raw materials such as cotton, blended fabrics, silk for the production of clothing.

Why is it good at knitting?

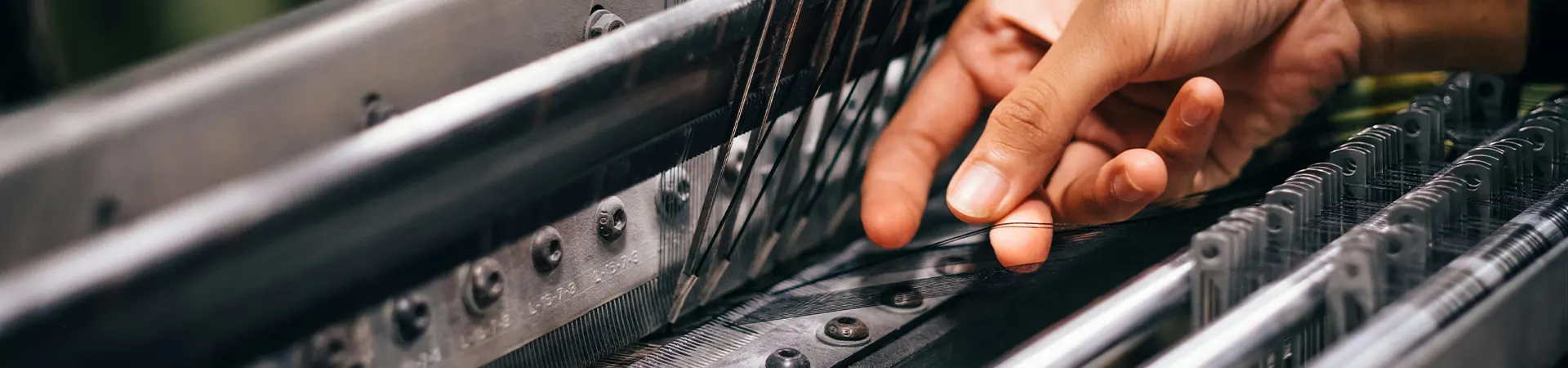

Every factor affecting knitting accuracy has been taken into consideration.

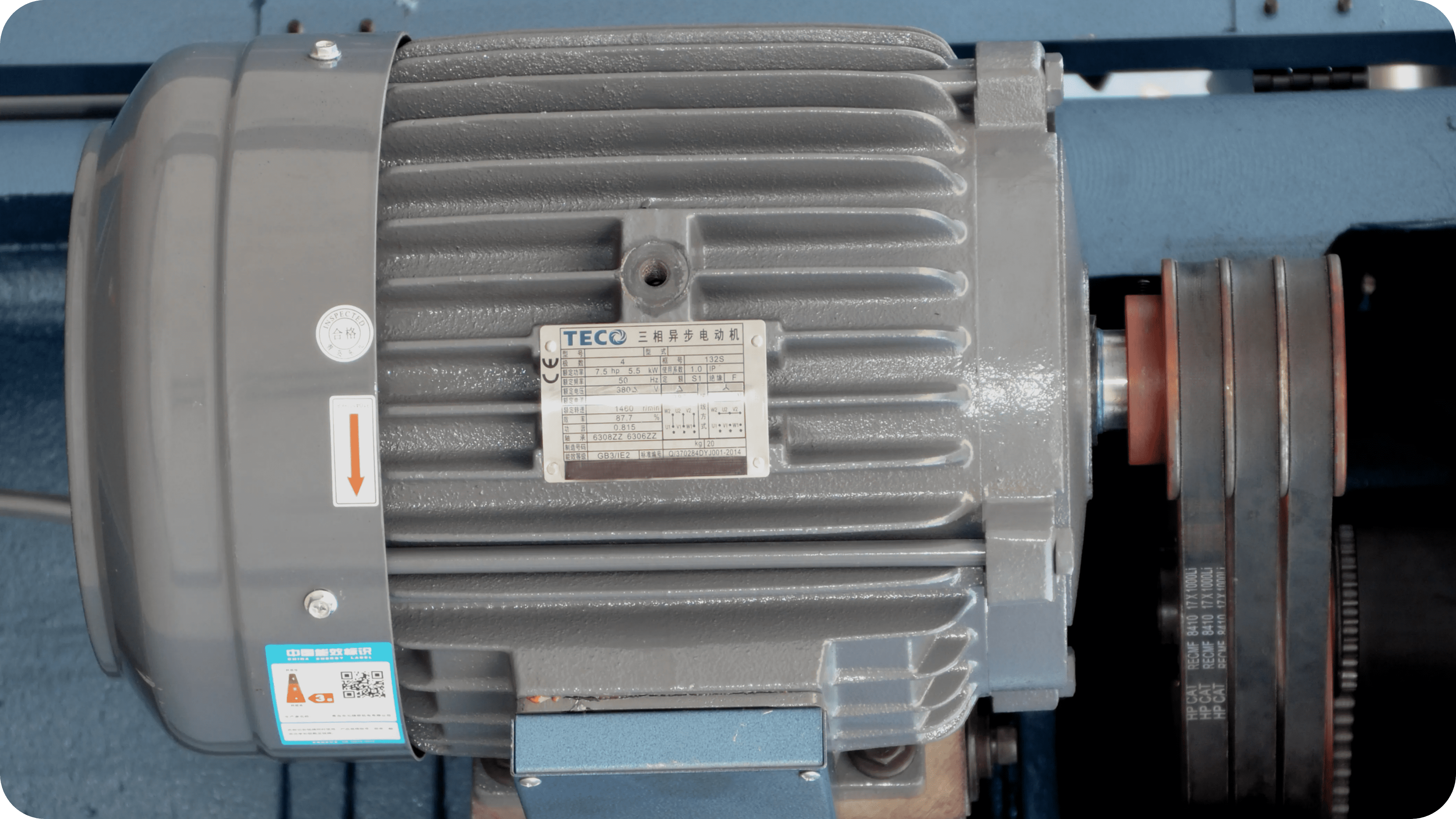

Control system, transmission system, motor, cam, etc,Where you cannot see are details.

|

|

|

|

|

|

Product Features

|

|

|

|

|

Basic Parameters

Diameters | Feeders | Gauge | RPM |

30"-44"∕3 feeders per inch | 90F-132F | 12G-40G | 18-35R.P.M |

30"-44"∕3 feeders per inch | 96F-126F | 12G-22G | 20-26R.P.M |

Optional Device

Standard Equipment | Optional Equipment |

Positive Feeding Units | Spandex preparation device |

Automatic Lubrication Device | Lycra Feeding Units |

Needle And Fabric Detector | Yarn Input Measuring Device |

Open Width Frame | Central Stitch System |

Automatic Cleaning Device |

|

Yarn Creel System |

|

Know us, Choose us, Be us

Sign up to receive the latest news, announcements, and promotions!